NOISE is just sound that we don’t want or like. From before we were born, everyone of us with hearing, have lived with sound. Sound surrounds us, 24 hours a day, 7 days a week and for 365.25 days per year, constantly bombarding us with sensory input, the vibrational energy travelling through the air and hitting our eardrums where the mechanical becomes electrical impulses in the brain that we ‘hear’ as sound.

It’s not like we have ear-lids that we use to shut it out. Instead, our brains have adapted themselves to filter out background noise. We learn to become accustomed to a certain level such as a fan or air conditioning, traffic noise or even breathing. We notice when it changes.

Most of us have experienced noise issues first-hand. Human voices, dogs barking, babies crying, the thud of bass music at 3am. But it can be more subtle, chairs scraping, footsteps or even light switches and toilet flushes. It can become an emotional stressor real quick when you are living beside these noises constantly.

How we hear sound, is a distinctly personal experience. Some people love traffic noise, it becomes associated with urban thrills and experiences, the hustle and bustle of city life. For others it is too noisy, too urgent and they prefer less background noise, they might enjoy the birdsong or rustling leaves that get masked by the predominantly urban police sirens and buses.

These, and many other factors such as the proximity of the sound source to the receiver, frequency ranges and wavelengths etc. need to be taken into account by Acoustic Consultants, Architects and Acoustic Material Suppliers when designing buildings and partitions that can insulate or absorb noise in a predictable way.

The same five key principles of physics apply when trying to mitigate noise levels in a building. Understanding these elements will help make clear the concepts of Soundproofing or Sound reduction.

Soundproofing Principle 1 – Mass

This is a really straight forward principle, the more mass of material the harder it is for sound to move it. The issue is though that you need it to be a REALLY heavy additional mass to make a big difference. As a guide, doubling a wall mass will get you an additional 6dB. The next 6dB will require doubling of the whole wall mass again. Simply adding an extra layer of plasterboard to an existing heavy wall will only give you a very slight decrease in sound transmission.

Core Product recommendation: Mass Loaded Vinyl (MLV)

Soundproofing Principle 2 – Mechanical Decoupling / Isolation

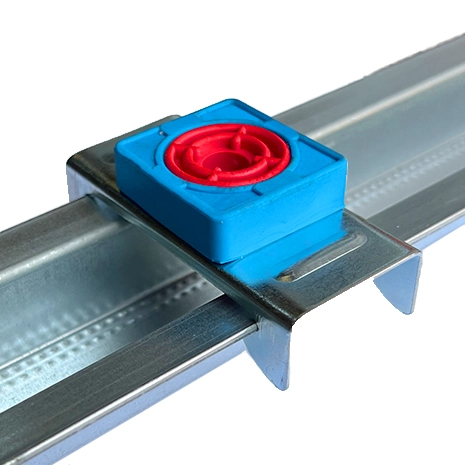

When one solid material is in contact with another solid material, the sound vibration will pass easily through from one to another. If they can be separated so that they are not 100% in contact, this will reduce how much energy is passed through the system, because it has to then jump through air.

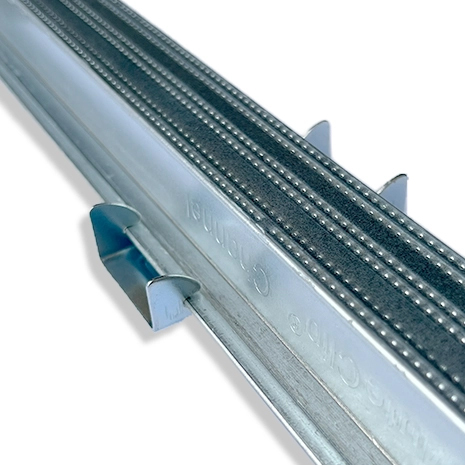

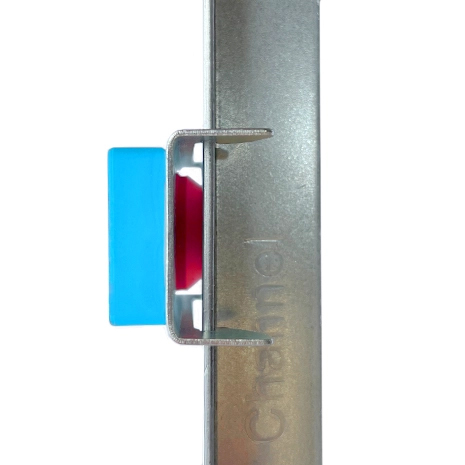

There are several interpretations of this, from staggered studs, to dropped ceilings, resilient channels and sound isolation clips.

What does need to be understood however, is that by this decoupling or separation of two plasterboards for example, the cavity produced will have its own natural resonant frequency that needs treating with absorption material such as dense mineral wool. If you don’t do this then it can actually make things worse in the low frequency range, rather like a drum effect.

Core Product recommendation: MuteClip® The dual impedance sound isolation clip.

Soundproofing Principle 3 – Absorption

This is a commonly misunderstood principle. People will use ‘sound insulation’ and ‘sound absorption’ interchangeably, but they are fundamentally different. Absorption material is typically fibrous, squashy and low density and is used to stop reverberation inside a cavity or room. Insulation is heavy, rigid and designed to stop sound passing through it like plasterboard. So, in a typical hollow wall or timber joist ceiling, both are required. The absorption is required between the joists or studs to reduce the sound bounce or reverb between the floor and the ceiling below. It turns the vibrational energy of sound into heat, albeit low levels. Imagine shouting through several duvets, absorbing sound in every direction, it takes more energy from you to be heard.

While almost any absorption material within a wall’s cavity will help reduce some degree of sound, the lightweight thermal, candy floss type fibreglass will be of limited benefit. It will not help with the problematic lower frequencies at all. At a relatively low m2 price, why not invest in some heavy duty 60kg/m3 acoustic mineral wool? You get a good dB reduction per invested £.

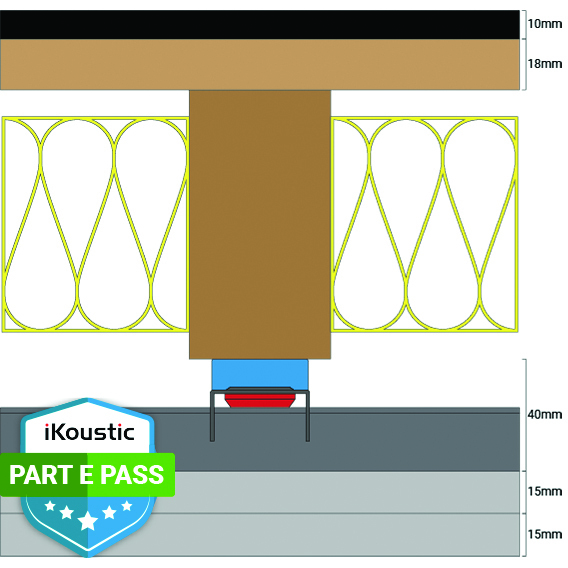

The use of absorption is most effective when the ceilings are decoupled, otherwise the joists connecting the floor to the ceiling will simply bypass the mineral wool. This is where either isolation clips below or acoustic matting above will help by extending the cover and depth beyond the joist thickness.

Core Product recommendation: Dense Mineral wool 60kg/m3 density

Soundproofing Principle 4 – Resonance:

Everything with Mass has a natural resonant frequency. It’s easy to get it to vibrate at this frequency but very hard to get it to vibrate at a different frequency.

A washing machine can easily vibrate a heavy floor when its spin cycle vibrates the floor at the floors natural frequency. It’s easy to push a child on a swing at its natural frequency but try changing the frequency and you are likely to get a heel in the teeth!

In other words, even when fully treated with all of the above principles, sound will still resonate a decoupled and insulated floor if the right frequency hits it with enough energy. Low frequency has more energy than high frequency so you can understand why bass is more difficult to manage as this is more in the range of the natural frequency of heavy floors and walls. Notice how a Bass Sub on a floor vibrates liquid in a coffee cup next time you are watching Die Hard 36!

So how can we address this?

Lowering the resonant frequency of the floor by adding more mass.

A floating floor is ideal: we can lower the frequency at which the wall wants to resonate by making sure there is plenty of mass in each wall that makes it harder to vibrate and by adding absorption in the cavity void. This can help push the resonance point low enough that only the deepest frequencies will vibrate through the wall. Even with this treatment a subwoofer will almost always disturb your neighbours, as these treatments can only push the resonant frequency so low.

Core Product recommendation: MuteCradle

Damping, reducing resonance by absorbing or redirecting sound, can go a long way to combatting resonance and conduction. An everyday example of this is a little pad of material on the underside of your metal sink. This dampens the vibration in what is essentially, an upside down bell. Everytime the water hits it, it rings like a bell. This visco elastic material dampens the vibration and reduces the natural resonant frequency. This material can be used between two sheets of plasterboard as well as on metal to decouple and add mass.

Soundproofing Principle 5 – Conduction:

This is essentially the transmission of sound through vibrations in solid objects connected to each other. Conduction is a very efficient way to transmit sound. Tap a radiator in one room and listen to the barely reduced sound level next door.

From a floor perspective, you can appreciate that any floorboards and plasterboard directly connected to either side of the joists studs on either side will never perform well even with mineral wool in the void.

Sound will also travel through indirect routes largely via conduction, and this is called flanking noise. Think of a lightweight hollow stud wall connected firmly under a ceiling. Any footsteps on the floor above will travel down through the joists and plasterboard into the stud wall. Mechanical Decoupling or Isolation is one of the most effective ways to combat conduction, and is why the most effective soundproof floors, ceilings and walls are completely decoupled, so there is no direct conduction path for the sound to travel. A regular way of decoupling flooring is by using an isolation strip or damping using a visco elastic membrane.

Core Product recommendation: TecSound SY70

Balancing these principles together

I am sure you can see that each of these principles need considering on its own merits as well as balancing or tuning them together. Decoupling a ceiling will help with transmission of mid-high frequency sound but will increase resonance and sound transmission at lower frequencies unless you add absorption into the void.

While the principles are pretty straightforward, combining them for best effect is really the territory of a specialist. This is where acoustic systems and hybrid products come in.

Core Product recommendation: MuteMat®3 Plus

So how does this translate into Acoustic Flooring?

Acoustic Flooring is essentially a floor build up using the above principles that inhibits sound energy from passing through it so its quieter on one side than the other, whether that is floor to ceiling or ceiling to floor. The side that the noise is created on is known as the Source, the side it is measured on is the Receiver.

The actual solution depends on the noise source issue you are looking to address or the sound pressure level reduction or noise reduction goal measured on the Receiver side.

To reduce Airborne noise it will include the ‘Adding Mass’ solution, to attenuate impact noise, the solution will include ‘Decoupling’ layers. Some products specialise in one area or another, a few hybrid products will do both.

So Acoustic Flooring exists as a solution based on these 5 principles of physics. It can attenuate airborne noise such as voices from above or below it. It can minimise impact sounds like dragging chairs or footfall. It can provide compliance with Building Regulations should your planning application require it. What’s more, all this happens out of sight, below the final floor finish.

Indeed we might suggest that the best acoustic flooring solutions are ‘Not Seen And Not Heard’.

iKoustic – Creating Quieter Spaces Together

iKoustic® is a UK based acoustic product specialist that design, manufacture, and supply sound insulation solutions for buildings. Our products and systems are focused on reducing noise transfer through floors, walls and ceilings.

If you have a requirement to reduce noise in your building project, simply contact iKoustic® and we will be delighted to assist you in producing a material specification that will enable you to meet the specific acoustic requirements within your Space.

Our innovative, recycled and technically advanced product ranges are class leading in performance, durability and ease of installation.