There are so many elements to consider in the creation of a bathroom or wetroom, in terms of both practicality and aesthetics: it must be fully waterproofed and able to cope with material movements, it must drain at the appropriate rate, it must project a certain imagel, be it vitality or tranquillity … and that’s before you even start to consider how your chosen products will work together.

It’s a finely tuned balancing act by anyone’s reckoning, but it doesn’t have to be difficult; a Schlüter®-WETROOM system not only contains all the items that you need for wetroom preparation and tile and stone finishing, but also eliminates compatibility worries, with all products having been designed to work together.

The benefits of employing such a system can be felt across the construction chain—with your entire specification solution obtained from one source, troubleshooting and admin are easier and there is a clear point of contact for any advice, aiding timely project progression at every step.

Proper attention to preparation and finishing enables a beautiful and long-lasting finish for an installation; for each potential problem you’ll need to address, Schlüter offers a targeted solution.

Problem: Guaranteed Waterproofing Provision for Walls

Solution: Schlüter®-KERDI-BOARD and Schlüter®-KERDI-200

As well as being the death knell to an installation, water penetration can cause severe damage to the fabric of a building; poor moisture management can often result in the closure of rooms and loss of revenue, not to mention costly remedial works. To prevent this occurrence, it is essential to employ the appropriate waterproofing systems, installed beneath the tile or stone covering.

Schlüter-Systems offers an ideal solution to the creation of a CE Marked waterproof assembly for the walls of your wetroom installation—the tile backerboard, Schlüter®-KERDI-BOARD. There are a variety of backerboards on the market, but a number of them are merely water-resistant, requiring the installation of a waterproofing membrane in addition to the backerboard itself. By contrast, KERDI-BOARD requires no additional finishing processes to make it waterproof, reducing two steps to one and saving considerable time on-site. To complete the assembly, joints are then sealed using waterproof sealing tape, Schlüter®-KERDI-KEBA, and sealant adhesive, Schlüter®-KERDI-COLL-L. The area immediately surrounding a pipe opening is often a tricky one to waterproof and can be tackled with Schlüter®-KERDI-MV waterproofing collars. These collars feature a fleeced outer area and an elasticated fleece-free centre, the latter of which is stretched over the protruding pipe to achieve tight-fit protection against water ingress.

The light weight of KERDI-BOARD does not compromise its strength and it is able to support up to 60 kg per square metre, making it perfect for supporting all manner of tile and stone choices. With seven thicknesses available – ranging from 5 – 50mm – this backerboard is multi-talented; whilst the boards at the thinner end of the spectrum are designed for use over existing substrates, latter thicknesses can be used as construction panels to create features such as shelves, partition walls and seats, allowing for complete freedom of design. Within the range there are also grooved boards for the creation of curved features, as well as preformed shower niches, and angle and U-shaped components for pipe panelling; all of which are designed for easy and targeted specification.

For situations that demand the use of a water-resistant board, Schlüter-Systems can provide the waterproof tiling membrane Schlüter®-KERDI-200, which can be laid over the board and sealed using the same easy steps as KERDI-BOARD.

Problem: Preventing Cracks in Tile and Grout, and Guaranteed Waterproofing for Floors

Solution: Schlüter®-DITRA range

Cracking and debonding of tile and stone coverings are two of the most obvious problems encountered with wetroom installations and floor-level showers. They are incredibly common and are the most visually apparent symptom of an installation failure. However, with the use of a modern uncoupling system, these problems can be prevented.

Schlüter®-DITRA 25 is the unsurpassed uncoupling membrane for tile and natural stone installations, first entering the market in 1987. Its solid history, combined with its CE Marked waterproofing capability, has made it an incredibly popular choice worldwide for ensuring crack-free tile and stone floor coverings.

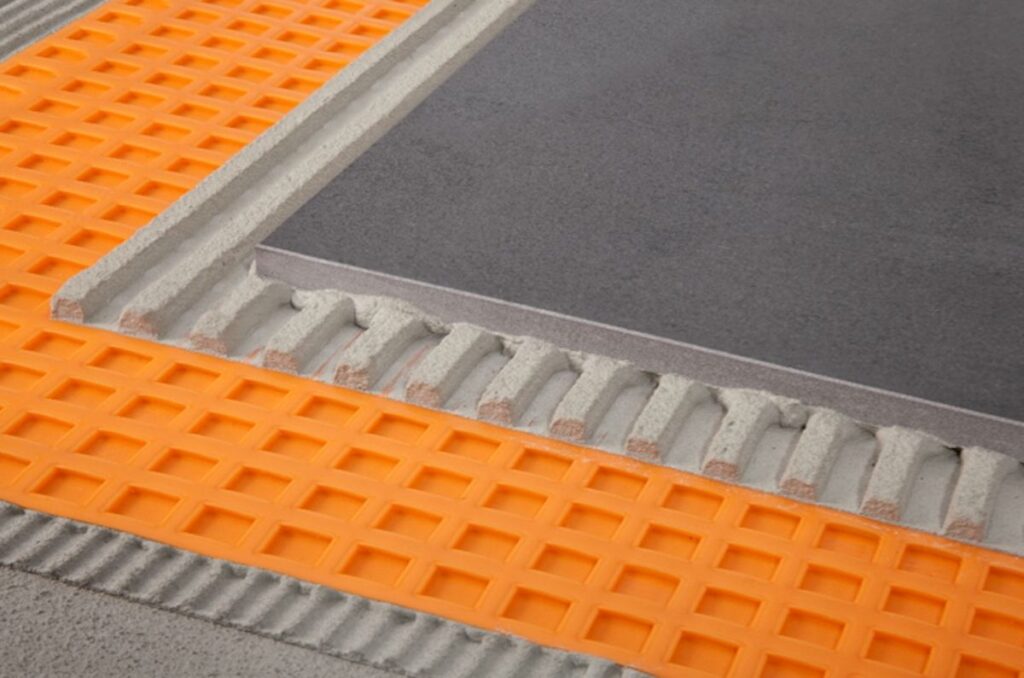

DITRA 25 is a polyethylene membrane with a grid structure of square cavities, each cut back in a dovetail configuration, and an anchoring fleece laminated to its underside.

The tile adhesive mechanically locks into cut-back indentations on the topside of the matting, eliminating the need for additional anchoring mesh. This mechanical lock means that the adhesive does not adhere to the mat, avoiding the formation of a direct bond and allowing for independent movement.

The geometry of DITRA 25 allows for the absorption of lateral movement in every direction. Through its two-layer design, this uncoupling mat truly separates the substrate and tile or stone covering by creating essential free space between the layers in which the matting can move safely, reacting to the movement of the substrate and surface independently of each other.

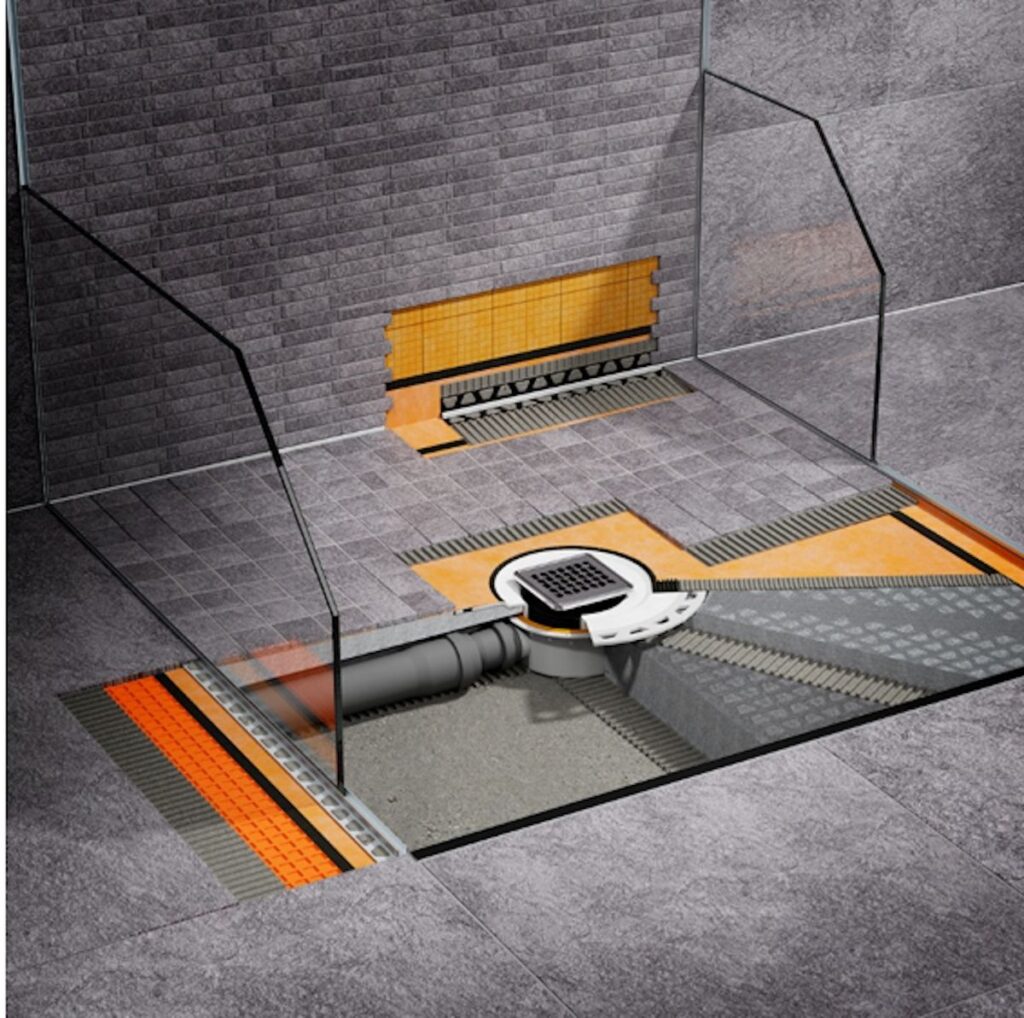

Using DITRA 25 as a waterproofing system for the floors of wetrooms and floor-level showers is easily achieved by carefully sealing the mat joints and connections with floors and walls using KERDI-KEBA sealing band and KERDI-COLL-L sealant adhesive.

Building on the success of DITRA 25, further specialist uncoupling solutions have been developed for particular applications. Schlüter®-DITRA-HEAT matting is an integral component of the electric underfloor heating system. Schlüter®-DITRA-HEAT-E allows for the creation of low-height and multi-functional heated surfaces. Schlüter®-DITRA-DRAIN is a combined uncoupling and drainage solution, developed for exterior use, that ensures proper moisture management for balconies and terraces.

Problem: Ensuring Adequate Drainage Slopes

Solution: Schlüter®-KERDI-SHOWER and the low height shower board in the KERDI-SHOWER-LTS range

The tile or stone covering in the shower area must be sufficiently sloped to allow for appropriate drainage and the flow of the showerhead must be less or equal to the flow rate of the drain. Falls in the floor gradient should be between 1 in 80 and 1 in 35. This is easily achieved with the prefabricated levelling and shower tray components of Schlüter®-KERDI-SHOWER, which are available with point or component linear drain systems.

The low height shower tray within the Schlüter®-KERDI-SHOWER-LTS range offers even more benefits due to its reduced height: it provides a fall of 1 in 80, in comparison to many shower trays currently on the market which have a fall of 1 in 50. Whilst this is, of course, suitable and compliant, it offers a significant height reduction as well.

Problem: Balancing Practicality and Aesthetics in Drain Design

Solution: Schlüter®-KERDI-DRAIN and Schlüter®-KERDI-LINE

In the point drainage system, Schlüter®-KERDI-DRAIN, the surrounding area falls at four points to a single point where the water flows away. The Schlüter®-KERDI-LINE linear drainage system offers an alternative solution, whereby water drains away via a channel length. Both systems are available in horizontal and vertical variants, with options to accommodate low assembly build-ups as well as flow rates ranging from 0.4 – 0.8 litres per second.

There are a number of modern grate and cover options available to complete the drain specification. For the ultimate finish with a continued surface of tile or natural stone, Schlüter®-KERDI-LINE-D was introduced to the range; this offers a frameless covering support specifically designed for showers made from tile and natural stone.

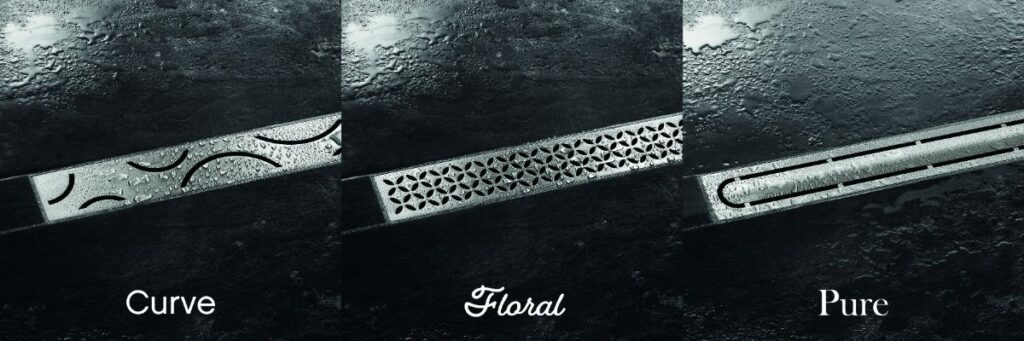

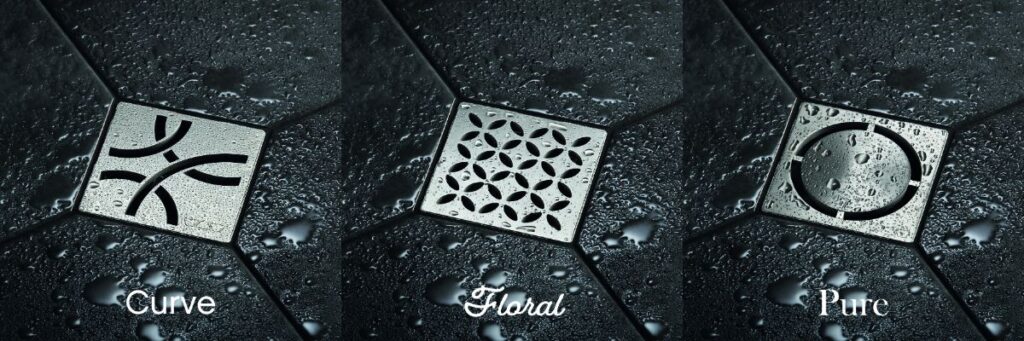

Where the grate needs to act as a feature, there are a range of stainless steel designs available across both point and linear drains, including the Floral, Curve and Pure options of the designer Schlüter®-KERDI-DRAIN-STYLE/KERDI-LINE-STYLE ranges, adding yet more contemporary finishing possibilities to the specifier’s toolkit.

The Schlüter®-KERDI-LINE-G3 is a stainless-steel drainage channel which can be fitted without the need for drilling or screwing. It complies with BS EN 1253, providing a 50 mm water seal and anti-blockage based on an 8 mm ball bearing test.

Problem: Integrating Storage Provision

Solution: Schlüter®-KERDI-BOARD-N and Schlüter®-SHELF

Conveniently positioned storage for toiletries improves the usability of a wetroom. There are a number of ways to achieve bathroom shelving and one of the most common is to drill through the finished covering to attach a shelf – this risks damaging the tile covering and penetrating the waterproofing below, causing aesthetic and practical issues.

An alternative to the above scenario is to plan for integrated shelving, in the form of a shelf with anchoring legs installed below the tile covering or a niche that forms part of the waterproofing assembly. Both these options offer a sleeker end result in comparison.

Schlüter®-KERDI-BOARD-N is a range of pre-fabricated niches for the creation of recessed shelving. Fully compatible with the rest of the Schlüter®-KERDI range, four sizes of niche are available, with the larger two inclusive of a dividing shelf that can be installed at the desired height. The result of a niche installation is storage provision that blends perfectly with the chosen tile or stone, as the product is completely tileable in-line with the rest of an installation.

For statement shelving, Schlüter®-SHELF offers a striking range of options. These shelves utilise the same designs available in the Schlüter®-KERDI-DRAIN-STYLE/-KERDI-LINE-STYLE drain grates, allowing for co-ordination across the two features.

This means that Floral, Curve, Wave, Square and Pure are available for shelves and drain grates.

Corner, niche and conventional shelf formats are available, including certain options suitable for retrofit. All are installed to flow with the grout lines of an installation and are available in a choice of brushed stainless steel or one of Schlüter®-TRENDLINE textured colour finishes.

Problem: Auxiliary Moisture Management

Solution: Schlüter®-DITRA-HEAT-E

Wetrooms are ripe areas for the gathering of condensation—which, if not dealt with effectively, can cause mould to grow. Under-surface heating is an excellent addition to a wetroom, serving to dry out any residual moisture, provide additional luxury and optimise the space available.

The problems that are encountered in tile and stone installations are exacerbated once heat is added to the equation; with the flooring assembly experiencing a greater range of temperatures, cracks in the tile or stone covering become all the more likely. For this reason, the uncoupling technology found in DITRA 25 can also be found in the electric underfloor and under-wall heating system, DITRA-HEAT-E.

As the system incorporates both uncoupling and underfloor heating, fewer layers are required in the flooring assembly—a traditional system can require numerous products, including insulation board, underfloor heating mat, uncoupling membrane and encapsulation layers; all of which add height to an installation. DITRA-HEAT-E-DUO—the latest iteration of the DITRA-HEAT-E system—not only provides underfloor heating, uncoupling, bonded waterproofing, crack bridging and vapour pressure equalisation, but also offers thermal breaking and impact sound reduction of up to 13dB, courtesy of a special 2 mm anchoring fleece on the system matting’s underside. The whole system comes in at only 7.5 mm thickness, making it suitable for both new-build and renovation projects and saving considerable height within a flooring assembly.

Problem: Appropriate Tile Edge Protection

Solution: Schlüter®-PROFILES

When care and consideration has been made to the tile and stone coverings in a bathroom it is essential to protect them and ensure that they will last for years to come. This is where Schlüter®-PROFILES come into play, offering both style and substance. With an extensive variety of wall and floor profiles to tackle common finishing dilemmas, from delicate, near-invisible finishing trims for walls, through to heavy-duty industrial profiles for floors, there is something that will suit each specific area and requirement.

To neatly finish tile and stone coverings against adjacent floor coverings of the same height, try Schlüter®-SHIENE, the original finishing threshold strip. For creating durable and slip-resistant stair nosing, Schlüter®-TREP profiles will protect the edges whilst offering DDA compliance.

Using screws to mechanically attach shower screens means that waterproofing is punctured and needs to be resealed. The Schlüter®-DECO-SG profile allows for screw-free installation of shower screens, featuring an anchoring leg that is bedded into the tile adhesive and a U-shaped recess into which the glass is inserted.

The above solutions are just a few examples of how Schlüter®-PROFILES can be incorporated into any bathroom design whilst providing reliable protection.

Accessibility in Wetroom Design – Providing Access for All

A significant amount of time and thought is invested into the design of bathrooms for architectural projects. One design aspect that is important to consider is how our needs may change over time and the accessibility of the bathroom, especially for those with a disability.

This is where barrier-free bathrooms or wetrooms with floor-level showers, easy-access sanitary ware and the provision of seating areas can offer a practical, future-proof solution. It is always advisable to specify ceramic or natural stone tiles with a high slip resistance and with the huge range of tile and stone available today, creating luxurious, stunning, yet safe slip-resistant surfaces is easily achievable.

The integration of heating into the tile and stone assembly makes for a safer alternative to radiators. NHS guidelines for surface temperatures in their own buildings (considering the elderly, impaired and the young – the most vulnerable members of our society) state a maximum of 43°C. Most underfloor and under-wall systems come in at least a few degrees below this.

Learn More about Specifying a Watertight Wetroom

The CPD seminar ’10 point plan for the perfect wetroom’ covers the key considerations in the design and installation of walk-in shower areas. Enhance and reaffirm your knowledge with this 45 – 60 minute presentation, held at your offices.

An integrated system solution, with products that are designed to work together, should be the specifier’s first choice when selecting products to use in shower areas and wetrooms. This provides the client with a single point of responsibility should any part of the system fail.

Key topics covered by the CPD seminar include: the benefits of an integrated system for wetrooms versus multi-manufacturer combined offerings, how point and linear drains can be hidden or accent the design, the requirements of waterproofing and how an integrated system offers peace of mind for a complete solution.