What to look for when choosing a fabricated underlay

A fabricated underlay is a wood-based panel which is applied to a subfloor/base/flfloating flfloor to provide a smooth, even surface in preparation for the installation of a floorcovering. The demand for good quality fabricated underlays has soared over recent years, undoubtedly driven by the phenomenal rise in the popularity of resilient flflooring.

Over many decades, hardboard has been used as an underlay in the flflooring sector, but just as resilient flflooring has evolved, so too has Finnish Fibreboard, and this has resulted in the development and launch of a new high-density fibreboard product that greatly surpasses traditional hardboard products.

Specifying sustainable fibreboard

The reason for the increased demand for an engineered fibreboard underlay is simple; LION Floor offers a cost-effective alternative to a good quality flflooring grade plywood, but without the common problems surrounding plywoods such as core gaps, veneer overlaps and delamination issues. Fibreboard also responds to environmental concerns surrounding the long-term sustainability issues of tropical hardwoods used in BS8203 compliant plywood production.

Therefore, demand for a homogenous high-density engineered fabricated underlay has sky-rocketed in recent years and this trend looks set to continue exponentially, in part owing to the sustainability credentials of LION branded products.

All our LION-branded products come from highly sustainable sources (predominantly PEFC-certified) and are in fact produced using by-products from timber sawmills in the immediate vicinity of our fibreboard mill.

There are so many elements to consider when designing a floor, in terms of practicality and aesthetics – and that’s before you even start to consider how your chosen products will work together – should you use a plywood fabricated underlay, or would a homogenous fully engineered fibreboard panel that guarantees no core gaps or veneer overlaps be a better solution?

Awareness of the system that lies beneath the flooring surface has to be built on two levels: a general comprehension of the reasons for using a fabricated underlay; and an understanding of the benefits that can be gained from using LION Floor as opposed to a plywood underlay.

Whereas in the past, installers would have to wet the hardboard in order to condition the board prior to laying, LION Floor is supplied pre-conditioned, so it has the same moisture content as a good quality tropical hardwood plywood underlay, between 8-10%, which means LION Floor underlay can be treated in exactly the same way as a BS compliant flooring grade plywood system, but without the many concerns associated with plywood underlays.

International standards

The international standard for LION boards is EN 622-2; while most readers of this article will be more focused on the UK’s own and very recently updated BS 8203:2017.

These standards look at different issues, with the European norm focusing primarily on the criteria surrounding the manufacturing process and general characteristics and technical properties of the board, whereas BS8203:2017 focuses solely on the issues surrounding resilient flooring.

To meet the exacting criteria laid down by the new BS8203:2017, only two materials are recommended as suitable products for use as a fabricated underlay for resilient flooring. In order to satisfy BS8203 fibreboard must comply with EN622-2 and be of type HB.H (oil tempered), and as LION Floor is preconditioned (see section 7.3.1 of the new standard) it can be used in exactly the same way as a BS compliant flooring grade plywood.

BS8203 states in 6.3.1 that all timber bases (including wood based floating floors – see 6.5.1) should be covered with a suitable fabricated underlay, and fibreboard is the only homogenous engineered underlay approved in section 5.1.1. LION Floor has been specifically designed to meet the standards requirements and the demanding conditions of a resilient floor. As the new plywood requirements in BS8203 exclude the vast majority of plywoods available on the UK market, LION Floor is an attractive and cost-effective alternative.

Greater versatility and better flexibility

As well as guaranteeing no core gaps, engineered LION Floor is available in 4.8mm thickness, which BS8203 states is comparable with a 6mm (5.5mm nominal) flooring grade plywood and for those heavy-duty contracts, it’s also available in 6mm thickness.

LION Floor is roughly double the density of a good quality hardwood plywood meeting the new BS8203 standards, which ensures it also comes with superior impact resistance.

Unlike most flooring plywood, LION Floor is available in a large variety of different panel sizes, enabling designers and contractors to ensure the flfloor surface is prepared with a minimum of waste, saving time and allowing greater opportunities to ensure underlay joints don’t fall on flflooring joints – again something that needs to be avoided as specified in BS8203:2017.

Installation

LION Floor is installed in exactly the same way as any good quality flooring grade plywood. This is detailed in BS8203:2017 in sections 6.7 and 7.3 which states all underlays should be at the equilibrium moisture content they have in service at the time they’re covered.

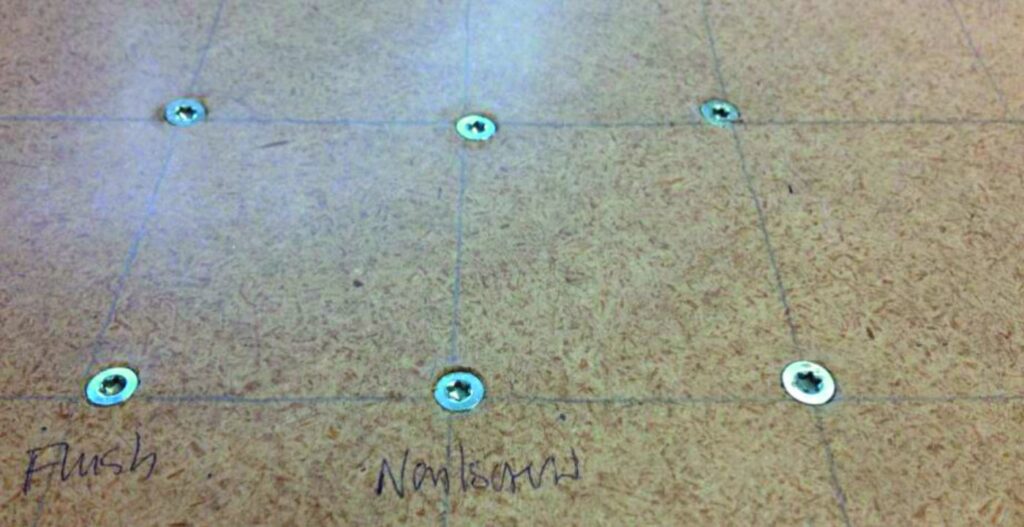

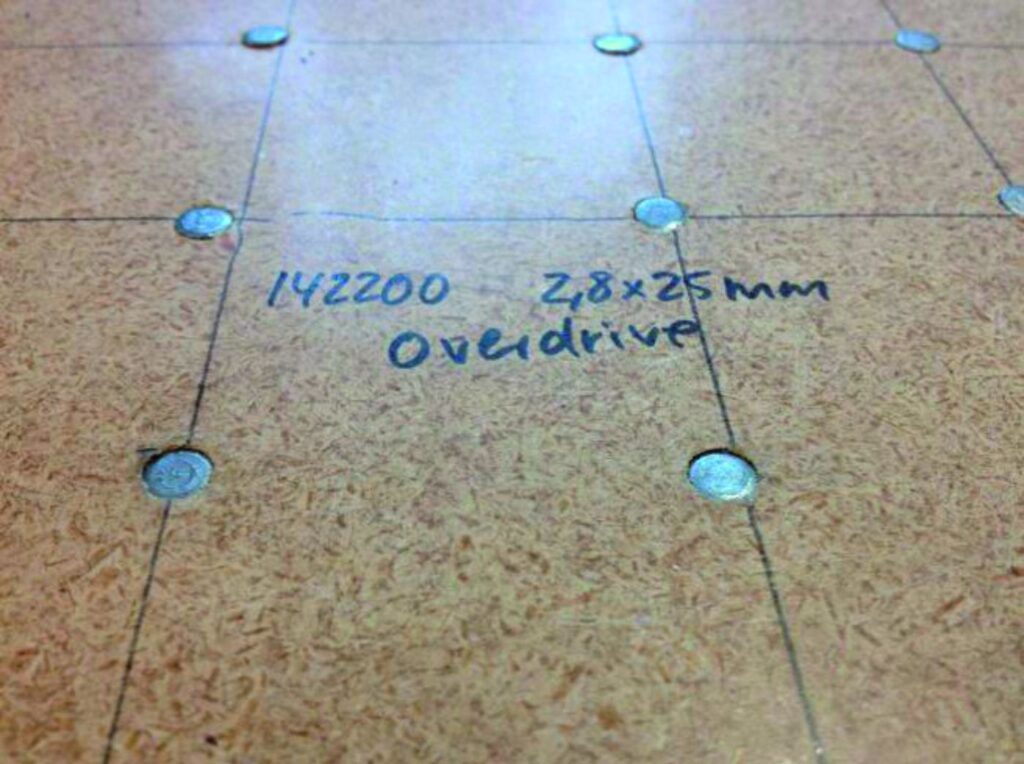

When fifixing, the best results are usually achieved using screw nails or ring shank nails. The length of the fixings should be at least 2.5 times the thickness of the underlay, but no longer than would allow them to protrude below the wood-based panel that they’re being secured to. For detailed installation instructions, consult our latest installation guide.

A cost-effective and greener alternative

For BS8203 compliant installations, the use of tropical hardwood flooring grade plywood is the norm, but this is not to say that these products are the best solution available. The homogenous engineered construction of LION Floor provides several advantages while maintaining the same installation method.

With a construction that’s less prone to failure and made from by-product of the wood industry, LION Floor is the cost-effective and more sustainable fibreboard alternative.

FINNISH FIRBREBOARD (UK)

07968 064861

sales@finfib.fi

peter.jones@finfib.fi

www.finnishfibreboard.com