In a world in which every brand is vying for an advantage over their competitors, creating experiences that are unique or memorable is one way companies can aim for recognition in the marketplace. Entrance mats featuring logos is nothing new, but advances in materials and production methods are making precision inlaid logomats a go-to choice for big brand refurbishments and fitouts.

First impressions count

Big name retailers such as Boots and Holland & Barrett have cottoned on to the idea that the humble entrance mat can sit at the centre of a successful entrance design. And going BIG is the way to do it; most entrance mats don’t actually cover enough space to allow footwear to be sufficiently cleaned, which is why properly specified entrance areas will often cover several metres in width and depth. This opens the opportunity to play with large designs, including oversized logos that ‘bleed’ off the edge of the mat or messaging that has a real impact.

The shift from print to inlaid

Jet printed fabrics offer a convenient and hugely popular way to create branded ‘loose lay’ mats that can be produced in small and large quantities. It provides a durable print finish and offers designers enough leeway to produce impactful designs, usually by selecting a set number of colours from a range of inks to suit the logo or design concept in question. Whilst loose lay mats can be moved more easily and, in most cases, washed, they are not usually up to large footfall entrances that must endure dirt and moisture walked in on the shoes and wheels of hundreds if not thousands of visitors.

Digital printing is another option for logo entrance mats. This tends to suit larger print runs of 30 or more individual mats, which makes them a great option as promotional tools where no cleaning benefit is expected, and the life of the product is more limited. Promotional logo mats are often used to support marketing campaigns in the travel and leisure sectors and are not limited in their use of colour. One of the key benefits to this type of logomat is the ability to replicate high resolution imagery and graphics, making them ideal when image is everything.

Printed mats are ideal for when higher quantities of mats are needed or when loose lay mats are enough to cope with the volume of traffic, however designers and specifiers are increasingly opting for an alternative way to introduce logos and graphic design into flooring installations.

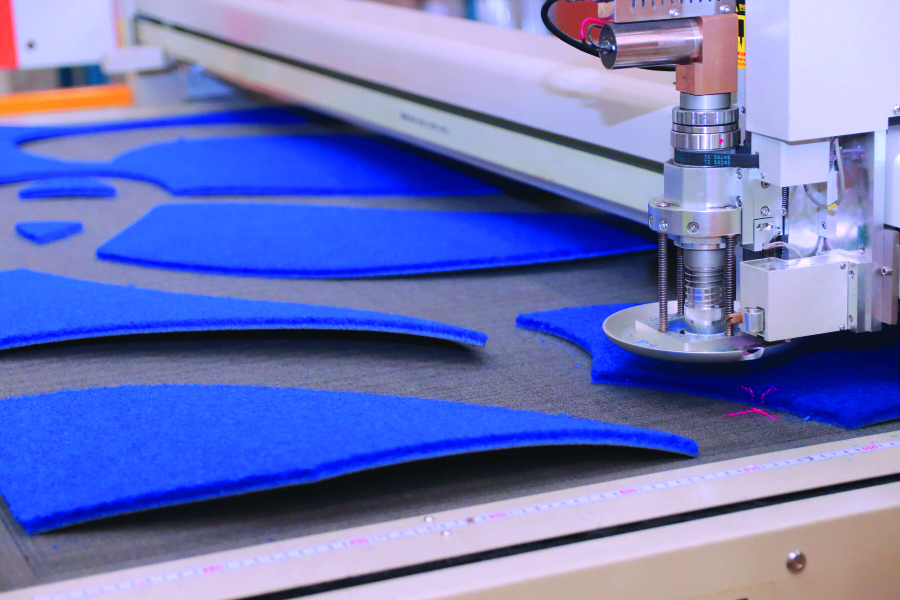

An inlaid logomat is one that combines multiple materials of solid colour together to create a larger design. The same pattern is precision cut out of the various raw matting materials, and then each piece adhered together like a jigsaw puzzle on top of a backing of rubber or vinyl. The precise cuts are usually made on an automated flatbed cutting machine, which is guided by a precise 2D CAD design of the overall mat. This method means that there is a wider array of available materials to choose from, and designs can even be inserted into Aluminium rail systems.

Material selection

Creating logomats by cutting materials, means that you aren’t limited to the more lightweight textiles sometimes used for loose lay logo entrance mats, which are dyed or digitally printed, and which can range from 0.4 kg / m2, to 0.9 kg / m2. Materials with heavier pile can be used as they do not need to go through a printing process, the pre-dyed material is cut into pieces to make up the larger design. COBA’s materials of choice for precision inlaid mats are Precision Nib and Precision Loop, which range from 2.7 kg /m2 to 2.9 kg /m2.

Using higher spec entrance matting materials to create logos in entrance areas means that they also benefit from aspects you might expect in other large format flooring materials, such as flame retardance and slip resistance. Both Precision materials cited above conform to BS EN 13501-1 Class Cfl – s1, and Precision Nib also benefits from being tested to holding a BS 7976-2 – low slip potential certificate. As we know, slip potential is a key factor any building design in order to reduce the likelihood of future accidents.

And beyond the technical benefits outlined above, these two products alone offer designers 33 different colour options to choose from, meaning that a huge combination of designs can successfully be replicated. Colours range from subtle neutral tones such as White, Charcoal and Light Grey, to bold and impactful material colours like Apple Green, Sky Blue and Red.

Only limited by your imagination

Inlaid logo mats are normally produced on cutting beds that measure around 2 m x 3 m, however this isn’t a limitation because larger entrance mats can be constructed using multiple ‘panels’, which are produced separately and then brought together on site. This means that designs themselves needn’t be limited to a single logo in the centre of the entrance area. Designs can feature multiple points of interest that offer a branding touchpoint, welcome messages, or directional arrows.

And for buildings that require a heavy-duty entrance matting solution such as an aluminum rail system needn’t miss out on the opportunity to introduce logos to their entrance either. Logo designs can be split into separate strips and installed into each rail, building up a design that appears to float on the underlying system. This combination of the durability of aluminum and the design aesthetic of an inlaid mat really creates an entrance that people will make people say ‘Wow!’

Design and practicality

The flatbed cutting process used for inlaid logo mats ensures that the design on screen is recreated to the nearest mm on the table. Complex curves and even small typography can be replicated thanks to the precise cutting arm that follows a preprogramed route around the material. Small blades of varying depths are selected to suit the material being cut, and once installed in the cutting head, move at high speed to provide smooth and clean cuts free from tears and fraying. Material isn’t wasted either, as the ‘off cuts’ can be stored for future projects.

Shipping inlaid logomats to site is also easy. Tile and Rail based systems will often require some finesse to install into a matwell, which is why we usually recommend using someone who is experienced in installation of entrance matting. However, depending on the size and shape of the project, inlaid logo mats can often be installed quite simply without any cutting on site. The main reason for this is that each project will be templated in advance to ensure a mm-perfect fit.

If your client’s existing entrance matting requires refurbishment, please don’t delay in contacting our entrance matting experts. They’ll be able to recommend the ideal solution to suit your environment and budget, call us on 01788 228 566.

See our full product range, projects, and latest articles on www.cobaflooring.com.