The popularity of recycled polyurethane foam underlay in the domestic sector, owing to weight, performance and value, has led to similar products being developed that are suitable for the commercial sector. Offering contractors a high-performance underlay that is easy to transport and handle onsite, recycled foam underlays are a growing force in commercial installations where exceptional recovery properties are a must to improving the comfort and wear of the carpet.

The secret to better performance

Not only does foam underlay provide better underfoot comfort, it also helps to extend the life of the carpet by absorbing the effects of footfall. Cushioning the carpet from repeated impacts, the right foam underlay can extend the life of carpet by up to 40%, making it essential in ensuring that carpet performs well in commercial environments. As well as extending the life of the carpet, foam underlay acts as a noise barrier, absorbing impact and airborne noise to make for a quieter environment. Additionally, an ability to provide thermal insulation also helps to reduce energy consumption.

A sticky situation

It is the ability of a recycled foam underlay to be installed using the double-stick method, where the underlay is tackified to the subfloor and the carpet then permanently glued to the underlay, that is important for many commercial projects. With more intense use and much larger areas, this is the most secure method for commercial environments and it also speeds up carpet and underlay up-lift at time of replacement. It is important to note that many foam underlays are only suitable for use in stretch-fit applications, common in residential installations, so these should be avoided if specifying underlay for larger commercial interiors.

Adhering to British Standards

Any foam underlay chosen for use in a commercial environment should meet the end use classifications set out in BS EN 14499:2015 Specification for Underlays for Textile Floor Covering. This determines the suitability of an underlay to resist compression over time. Underlays tested undergo a series of tests that determine thickness, compression and recovery before and after static and dynamic loading, as well as resistance to breaking and cracking.

The standard is crucial in ensuring that foam underlays will perform under intense use; any underlay chosen for a commercial environment should at least meet Class GC/U General Contract Use. Ideally, for areas of high traffic such as receptions, corridors and lobbies, the underlay chosen should meet HC/U Heavy Contract Use. With foam underlays produced globally, it is important to make sure that the underlay has been tested in accordance with BS EN 14499:2015 in a recognised UK-based testing centre. Failure to check this, could lead to a foam underlay that will quickly fall short of the expected performance.

A question of density

Meeting the requirements set out in BS EN 14499 is down to the density of the foam underlay linked to the product’s thickness, which can both vary depending on the comfort level required. Principally, the higher density the foam, the better long-term recovery it possesses and so the more suitable it is for use in high traffic applications. At Floorwise, densities are categorised from Standard Density through to Ultra High Density. All underlays are tested in accordance with BS EN 14499 and Ultra High Density Plus (180kg/m3) rated products achieve HC/U, so are suitable for use in commercial environments.

With some of the highest recovery rates of any underlay – 90-95% for PU compared to 40-65% for some sponge rubber and felt underlays – Floorwise Ultra High Density foam underlays deliver exceptional long-term performance. With continued recovery from both static loads (furniture) and dynamic loads (footfall and wheeled traffic) they can help to prevent crimping of the carpet, as well as absorb the wearing effects of traffic.

More than just support

These Ultra High Density Plus underlays possess excellent long-term recovery, ensuring that they can withstand constant traffic, as well as help to increase the life of the carpet, but the density also has further advantages by making the foam underlays particularly good at combatting sound and providing thermal insulation.

A particularly good acoustic insulator, it is possible for foam underlay to provide high-levels of impact sound reduction – associated with footfall – as well as working to help combat airborne sound such as that from conversations and daily operations. Floorwise Lift and Tread underlays have been tested to absorb 35dB and 39dB of impact sound respectively, a considerable reduction that will have a noticeable effect in commercial locations.

Thermally too, Ultra High Density Plus underlays perform well, with Floorwise Lift and Tread again scoring through a TOG rating of 2.02 and 2.44 respectively. Helping to keep areas warmer, it is a great way to conserve energy in conventionally heated premises. However, caution should be used if specifying underlay for use with underfloor heating, as the high TOG value of Floorwise foam commercial underlays can affect efficiency of the system.

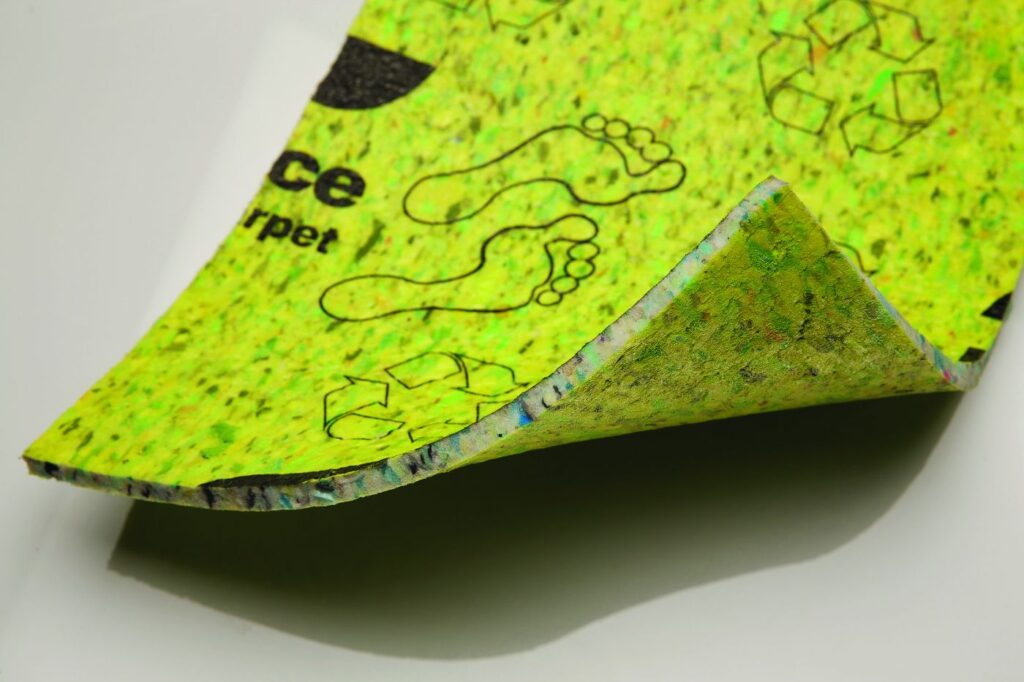

Recycled and recyclable

Made from offcuts of foam from furniture and mattress production, plus other industries, all Floorwise polyurethane foam underlays are made using post-industrial recycled waste. First the foam is granulated and mixed with a binding agent into a cylindrical block of a predefined density. Subjected to steam at high pressure to cure the binding agent, the block is then dried before being peeled into rolls of the required thickness. Then, any necessary backings and layers – such as the stability-enhancing mesh grid – are laminated to the surface. Once it has reached the end of its useful life, the underlay can be recycled, making it a good choice for projects looking to minimise environmental impact.

Engineered with value

Using post-industrial recycled materials, rather than virgin sources, ensures that polyurethane foam underlays provide excellent value; particularly in comparison to the traditional combination underlays found in commercial environments. Offering similar performance, yet with a lower cost, foam underlays such as Floorwise Lift and Tread, are increasingly the go-to option across commercial interiors of all sizes.

Fitting and handling

Thanks to a roll weight well below that of other commercial rated underlay materials, polyurethane foam is preferred by installers for transporting to and handling on site. To meet current HSE lifting regulations, many underlay types suitable for commercial use require a two-man lift, but full rolls of Floorwise Lift and Tread can be carried by a single installer, a big advantage in multi-storey buildings. This low weight also makes them faster to install, helping to save time on installation. With this additional cost-saving, along with an already excellent value product and life-enhancing performance, foam underlays are an excellent choice in the majority of carpet installations.

With Floorwise Lift, contractors and specifiers have access to high-quality recycled polyurethane foam underlays suitable for both double-stick and stretch-fit applications. Tested in accordance with BS EN 14499:2015, Floorwise Lift is classified as suitable for heavy contract use in commercial environments. As a 9mm thick underlay, Floorwise Tread is classified with a luxury use rating, but with the same UHD+ density it is very much suited for commercial stretch-fit applications. Both Floorwise Lift and Tread can provide an underlay that will ensure long-term recovery, sound absorption and thermal insulation; all in a product that offers excellent value, easier handling and faster installation.

Floorwise

01509 673974

wiseup@floorwise.co.uk

www.Floorwise.co.uk