WHEN it comes to designing the interiors of public buildings, the comfort and safety of the people using them is of paramount importance. Consequently, flooring and accessories, like other products, must fulfil certain requirements in order that they may be specified and used in both new build and refurbishment projects. On ships and in offshore environments, the standards are particularly rigorous.

In the event of a fire at sea, there is a high degree of danger in all areas but particularly those with heavy footfall, such as in foyers, waiting areas and restaurants. It’s for these reasons that special safety precautions are necessary when it comes to the specification of products to be used in ship interiors, including the floorcoverings. The focus of these measures, regulated by the International Maritime Organisation (IMO), is the prevention and containment of fire.

So, floorcoverings and underlays must perform well when tested for fire resistance, but they must also look good. Working together, floorcoverings and the appropriate underlay can help to minimise fire risks, reduce noise, add warmth, and ensure a comfortable and quality finish that will perform better for longer.

What is the IMO standard?

From the IMO website:

‘As a specialised agency of the United Nations, IMO is the global standard-setting authority for the safety, security and environmental performance of international shipping. Its main role is to create a regulatory framework for the shipping industry that is fair and effective, universally adopted and universally implemented. In other words, its role is to create a level playing-field so that ship operators cannot address their financial issues by simply cutting corners and compromising on safety, security, and environmental performance. This approach also encourages innovation and efficiency.’

Manufacturers worldwide who wish to supply floorcovering products to the marine and offshore industry must comply with the IMO Fire Test Procedures (FTP) Code for flammability (Part 5) and smoke/toxicity (Part 2). These state that ‘materials must not be capable of producing excessive quantities of smoke and toxic products or not to give rise to toxic hazards at elevated temperatures’.

Materials which pass the IMO FTP tests must also meet the requirements of the Maritime Equipment Directive (MED) before they can be affixed with the ‘Wheel

Mark’ of compliance.

Manufacturers should have two levels of MED approval – Schedule B (product related) and either Schedule F (batch related) or Schedules D or E (process related). The product supplier must also provide a Declaration of Conformity to be kept on-board for inspection.

Types of IMO underlay

Floorcovering designs on cruise ships often incorporate patterns and texture, so the underlay systems need robust performance standards to ensure dimensional stability, appearance retention and increased life of the carpet.

IMO underlays also need to be quick and easy to install for interiors refurbishments, and suitable for use with both stretch-fit and double-stick application methods to ensure a quality finish.

Lightweight options are preferred to minimise fuel costs and so many IMO underlays are made from Polyurethane (PU) or Latex foam in a variety of thicknesses suitable for different areas. For example, spaces with high foot traffic will require a more robust and higher density underlay while rooms where comfort is more of a priority such as cabins may be more suited to a lower density underlay.

How IMO underlays perform

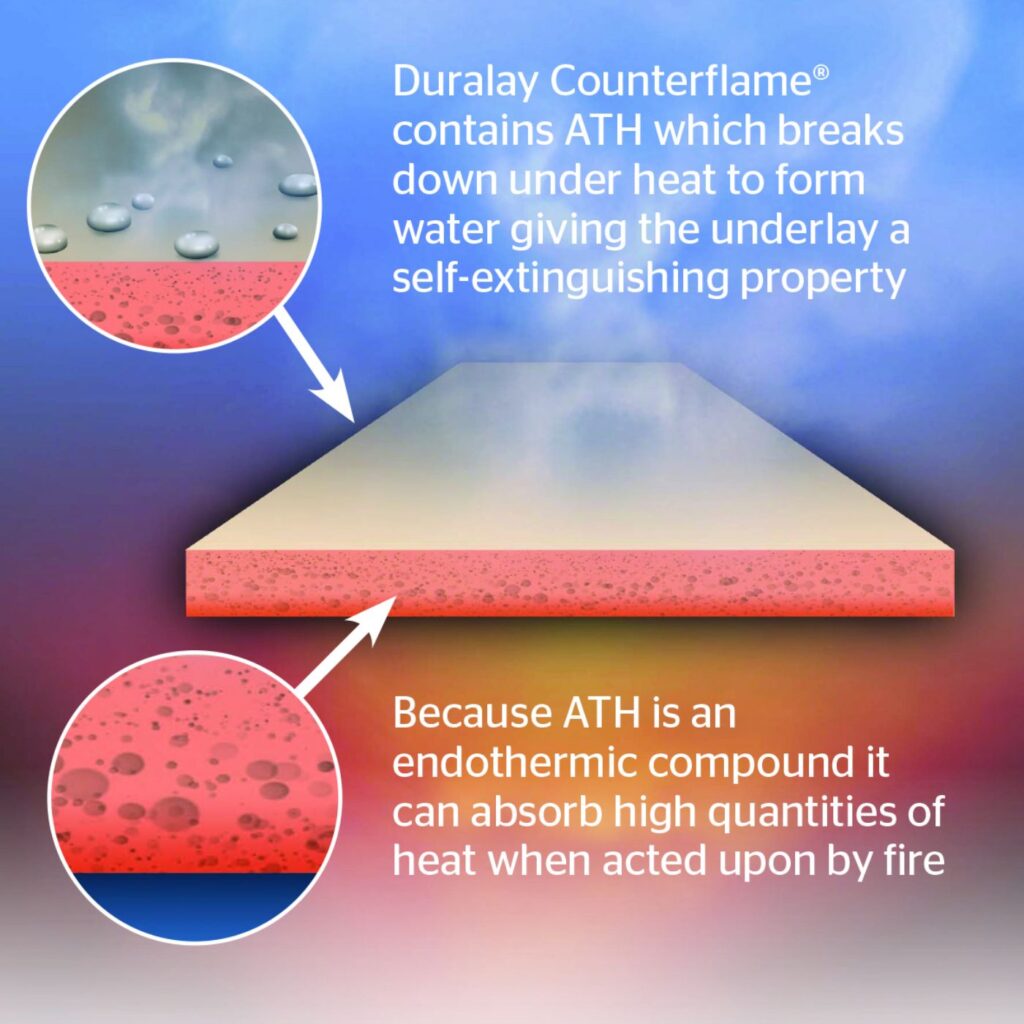

Some IMO underlays achieve a high degree of flame retardancy thanks to the inclusion of Aluminium Trihydrate (ATH), an endothermic compound which can absorb high quantities of heat when acted upon by fire. ATH’s ability to break down under heat to form water gives the underlay a self-extinguishing property.

As well as helping ensure the safety requirements of a ship and its passengers, quality IMO underlays can enhance the comfort and durability of the floorcovering.

In high-traffic areas, IMO underlays can protect and prolong the life of the flooring.

In private rooms and suites, IMO underlays can give a feeling of luxury and warmth and enhance the comfort of the passengers.

IMO underlays can also improve sound quality on-board – one of the main issues for specifiers and ship owners – and provide additional interior richness by reducing the level of structural and airborne noise to acceptable standards. This is particularly important in cabins, where passengers and crew want to be able to relax in relative peace.

As a significant contributor to the style of a cruise ship’s interior, floorcoverings can leave a lasting impression for passengers and ensure superior levels of comfort for everyone on-board. IMO underlays optimise the performance and appearance of floorcoverings as well minimising fire risks thereby ensuring the very highest safety standards are maintained.

Interfloor

01706 238810

Twitter @Interfloor1

Facebook @Interfloor1

LinkedIn @Interfloor

www.interfloor.com