There are compelling reasons to specify Quick-Step extensive range of laminate designs. They are sustainably produced, boast superb technical performance, and offer remarkable versatility in terms of decor.

As a result of continuous product development, these popular laminate floors are now equally appropriate for moisture-prone rooms, such as kitchens and bathrooms, as they are for living rooms and communal areas.

Quick-Step’s high-tech laminate offers today’s specifier a wealth of design features that make them suitable for any living or working space. Architects, designers, and property developers can now choose between products with different dimensions either in the classic tile format, as practical short planks, or as generously-sized country style planks. Today, there are just as many facets to interior design worldwide as there are individual lifestyles.

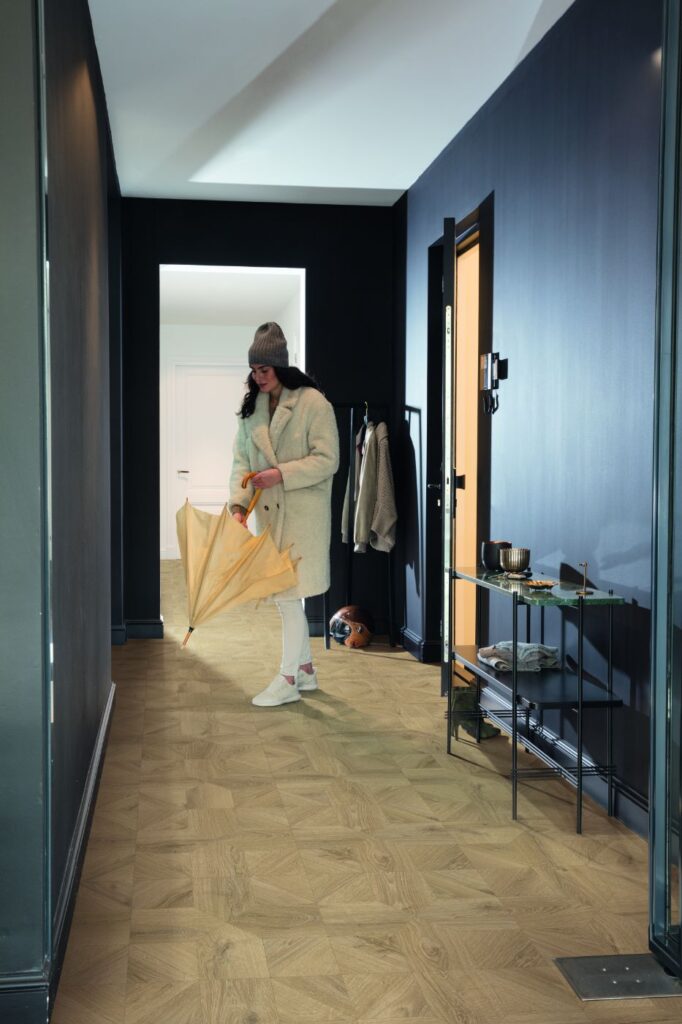

The Quick-Step range is also adaptable to a range of different styles; from modern, urban retro, and industrial, through to the enduring Scandinavian-inspired look.

The vintage and used aesthetic currently is one of the dominant themes in flooring. Also noticeable is the ongoing revival of classic forms, such as herringbone.

At the same time, the demand for wider and longer plank sizes has been growing, largely in response to large, open-plan room concepts, where the boundaries between living areas are increasingly blurred. And, as something of a counter-trend, the last 24 months have seen designs turning to a combination of different plank formats or short planks to add dynamism and pattern to laminate floors.

When it comes to choosing a decor, reproduction woods such as, teak, wenge, chestnut, merbau, beech, pine and walnut are presented by Quick-Step in a host of fresh varieties, although oak remains the market leader; a trend that seems set to continue.

Timelessly expressive and visually captivating, oak can be easily combined with other materials as desired, making it the ideal starting point for any development’s creative teams. Manufactured with imaginative designs in a range of new colours, textures and dimensions, oak is a very varied product category. Lighter to medium dark shades and various grey hues are very on-trend, but designers are increasingly drawn by laminate decors inspired by vibrant wood textures, with end grain elements and naturalistic growth rings. These high-quality synchronous embossed designs have surface textures that are precisely matched to the wood grain pattern, and with inishes in matt and semi-matt finishes, they give a near-perfect, natural impression to the finished floor.

Alongside a huge variety of impressive reproduction woods, Quick-Step’s laminate portfolio also include modern stone-effects, such as marble, travertine, terrazzo, and even concrete. The latest options include surfaces incorporating metallic effects or a patina of rust.

Overall, Quick-Step delivers a selection of colours and designs that underlines the sophistication of today’s best laminate flooring. These imaginative patterns and subtle effects makes laminate flooring a striking specification option.

This wealth of variety and colour is an indication of the increasing use of industrial digital printing within the European laminate sector. The leading producers, like Quick-Step, have harnessed this advanced and precise technology to great effect. It is also being used by accessories producers because it offers a quick and flexible way to satisfy specifiers’ requests for decors to match particular laminate floors. Accessory suppliers now have special designs available for specific architectural requirements, such as extra-slim skirting profiles that allow accurate installation even with narrow door frames.

Alongside the latest production and printing technology, continuous development has delivered sophisticated click systems with profile sealing and special moisture protection features. These cutting edge laminate jointing systems, such as Uniclic, have opened up new application areas, particularly in damp areas. This means that it is now possible to install a wood plank style laminate floor in kitchens and bathrooms. These new design have a non-slip surface, while high-spec HDF core boards, together with specially impregnated top layers and edges, mean that the laminate floors are now even more resistant to splashing and moisture.

Variety is also a key feature of today’s installation methods. The trend towards wider and longer planks continues. In addition, planks are commonly 9mm or 10mm thick, rather than 8mm, 9mm and 12mm; while chevron and design floors are particularly popular these days.

Thanks to the patented Uniclic installation system you can effortlessly click your floor planks together without the need to distinguish between right and left planks.

There is also a clear trend towards planks with subtle shading differences. When used in combination, this creates a harmonious, multi-faceted, look with very authentic colouration.

Bevelled edges, which form a handcrafted V-joint after the planks are joined, remain very popular. The latest designs enable further product differentiation, such as four-sided micro bevels.

The latest generation of laminate flooring – with its naturally renewable wood-based materials – are ecologically sustainable. With today’s emphasis on using wood from domestic cultivation, low-emission production technologies, and using waste wood in a biomass cogeneration plants. This all helps to make today’s laminate designs fit perfectly with the current demand for a balance between economy and ecology.

Fact-based Environmental Product Declarations (EPDs) are widely used by architects as vital basic documents for sustainable building. The updated generic EPDs for laminate flooring, produced by the EPLF (the Association for European Producers of Laminate Flooring), are verified by the IBU-Institut.

Laminate was one of the first floor covering sectors to offer environmental certification for their products; with the IBU publishing the first EPDs for laminate flooring back in 2009. Since then, there have been three EPD templates in accordance with ISO 14025, for DPL (direct pressure laminate), HPL (high pressure laminate), and PDL (printed décor laminate).

“The EPD certifies that laminate flooring has a very good ecological balance sheet, with extremely positive values for primary energy consumption and global warming potential,” explains Eberhard Herrmann, Chairman of the EPLF Technical Working Group. “The strengths of this floor covering are also evident in the indoor air quality. By choosing a product backed by an EPD, anyone wishing to select new flooring with environmental impact and sustainability in mind – whether for private or commercial use – has the strongest reason for choosing laminate.”

The message appears to be hitting home. In 2019, the worldwide sales of European laminate flooring totalled 447 million sq. metres, with positive growth in Western European markets. In the UK, sales from the leading European producers reached 32.6 million sq. metres, up from 29.8 million sq. metres in 2018, and the UK is now the third largest market in Western Europe.

This strong market position has been stimulated by the investment of companies such as Quick-Step in state-of-the-art production and print technology. This means that each new generation of laminate has extra functionality and additional product features that suit both the residential and the commercial sectors. With these laminate planks now certified as environmentally-friendly, low-emission products that comply with strict environmental requirements, it is little wonder that more and more specifiers are turning to laminate as a preferred surface solution.

When Quick-Step launched in 1990, the brand immediately put laminate flooring on the map. Over the past 30 years, the brand’s laminate flooring has been continuously improved, with even more life-like designs, structures, and performance.

There have been some significant landmarks along the way. In 1990 Quick-Step introduce Uniclic, a revolutionary glueless click system. This was followed, in 2001, by the launch of matching, true-to-nature structures, and the V-bevel. In 2004, Quick-Step introduced patina technology: a white oiled surface treatment. Three years later, in 2007, Quick-Step was the first company to introduce laminates for bathroom applications. This was followed, in 2009, Scratch Guard technology that increased scratch resistance up to 10 times when compared to regular laminate floors.

2014 saw the Introduction of Impressive (Ultra): water-resistant laminate. Here structure and design are pressed into the bevel for a more realistic look.

But 2019 saw a real game changer in laminate when Quick-Step launched Signature; a collection marked by refinement.

“Laminate flooring is part of Quick-Step’s DNA. Since the very beginning, our goal has been to create laminate that offers all the advantages of synthetic flooring, but that is undistinguishable from real wood or stone in look and feel. With our new Signature collection, we took laminate to the next level: we went further than ever before to get all the details right,” explains Laurent Meersseman, R&D Director’

“In terms of design, our new Signature collection is inspired by nature and pure influences, with white and light colours dominating the palette. We were also inspired by the re-emergence of warm naturals and exotic colours from Africa and Latin America. The common thread present in all these floors is an eye for detail and a sense of craftsmanship,” says Katrien De Vlieger, Design Manager

“Quick-Step is one of the few flooring brands worldwide with an in-house design team,” adds Meersseman. “Taking inspiration from architecture, art, fashion and real life, our expert designers embark on quests to obtain ‘perfect originals’: pieces of wood or stone that have the right look and feel to serve as a prototype for replication. In some cases, these originals are treated in-house with patina or wax to obtain a specific look.”

“Next, we comprehensively scan the original piece of wood, including the design and colour, as well as the complete structure with its cracks, knots and flowers,” notes De Vlieger. “The result is a huge, virtual 3D model of each piece, which is then refined by the designers. By getting rid of details that are too conspicuous, we craft a perfectly balanced design.”

The Quick-Step Signature range consists of 18 unique flooring designs. Brushed oak fits in perfectly with different interior styles. This floor is based on a brushed European oak with subtle cracks and knots. The brushed effect highlights the oak’s structure and makes the floor not only look but also feel like real wood. To accomplish this, Quick-Step developed a new technology to create 64 different depths on the surface as well as in the bevel.

The Cracked oak design was inspired by planks found in old train wagons. These were sanded until the wood beneath became visible. As a result, the surface is quite clean but with pronounced knots and cracks. The realistic, sharp edges along the cracks are the result of an innovative pressing technology.

To create Soft Patina Oak, the original planks were treated with oil to soften imperfections yet highlight the details of the décor. Subtle touches of matt finish give the floor a used look. In addition, the bevel looks distressed and splintered; just like a real wooden floor.

Patterns are making a clear comeback: on wallpaper, fabrics, and floors. Playing into this trend and offering a nostalgic herringbone pattern Chevron oak medium can turn any room into an eye-catcher.

Radiating warmth and softness, pastels are very much on-trend. Quick-Step has created Painted oak black to add power to pastel interiors with a bold colour contrast.

Patina oak grey plays into the Wabi Sabi trend towards perfect imperfection, and the Zen style in interiors. This look is all about subtle rough structures and natural elements. Asymmetry, rawness, simplicity, and natural imperfection of the materials create a pure and balanced floor.

Masculine and characterful, Waxed oak brown features unprecedented level of realism. Here the texture and structure of the floors breathe authenticity. The result is a design that fuses luxurious, classical and rustic elements.

Signature comes in 1,380 by 212mm planks, 9mm thick, with HydraSeal technology and four genuine bevels. It is covered by a 25 year domestic, 10 year wet and 5 year commercial warranty *on application. The full range of Signature designs is Painted Oak White, White Premium Oak, Soft Patina Oak, Brushed Oak Grey, Patina Oak Grey, Painted Oak Rose, Beige Varnished Oak, Brushed Oak Beige, Brushed Oak Natural, Brushed Oak Warm Natural, Natural Varnished Oak, Cracked Oak Natural, Patina Oak Brown, Brushed Oak Brown, Chic Walnut, Merbau, Waxed Oak Brown, and Painted Oak Black.

Unilin Flooring

www.quick-step.co.uk